Silicone Material Manufacturer & Solutions

Technology-driven factory specializing in custom specialty silicone materials with deep synergies with Liyuan Material Technology. Advanced R&D, production, and customization capabilities.

5000+

Square Meters Factory

12+

Technique Patents

30+

Laboratory Equipment

OEM/ODM

End-to-End Solutions

Our Difference

You need more than a silicone material manufacturer – you need an end-to-end innovation partner who engineers solutions from polymer design to real-world performance. While others sell raw materials, we deploy our 2,000㎡ CNAS lab with 30+ testing equipments to transform compound properties into your competitive edge.

Delivering premium silicone is our baseline; what truly defines us is co-solving your critical challenges. Whether it’s achieving UL94 V-0 in record time or optimizing tear strength for extreme environments, we measure success by the profits you generate in the marketplace.

Our Innovation Legacy

At Mikon Tech, we specialize in high-performance custom silicone materials, delivering excellence from lab research to mass production.

With over 15 years of technical expertise, we collaborate closely with leading partners to ensure innovative solutions tailored to our clients’ unique needs.

Key Advantages

Combining technical expertise, production strength, and quality assurance to deliver exceptional silicone solutions

Technical Endorsement

Ongoing collaboration with university research labs for cutting-edge material science insights

Manufacturing Strength

5000+ square meters modern factory with automated production lines / ISO system & 6S management

Quality Assurance

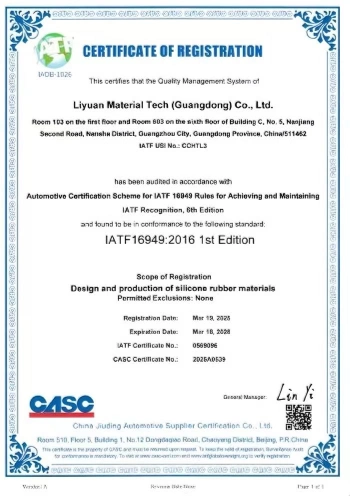

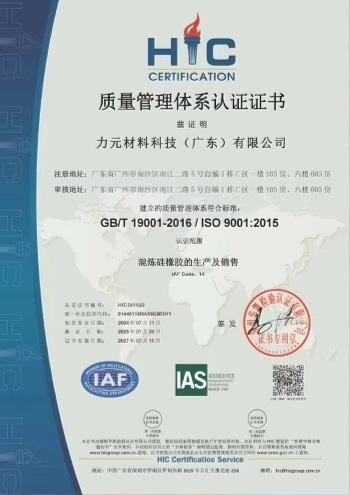

IATF16949/ISO9001 certification with UL certified product line

Craftsmanship and Customization Capabilities

Substitutable for Some Well-known Brand with flexible parameter adjustment

Supply Chain Advantage

Located in Pearl River Delta core manufacturing region

Core Products

Discover our most popular high-performance silicone materials and custom silicone rubber products

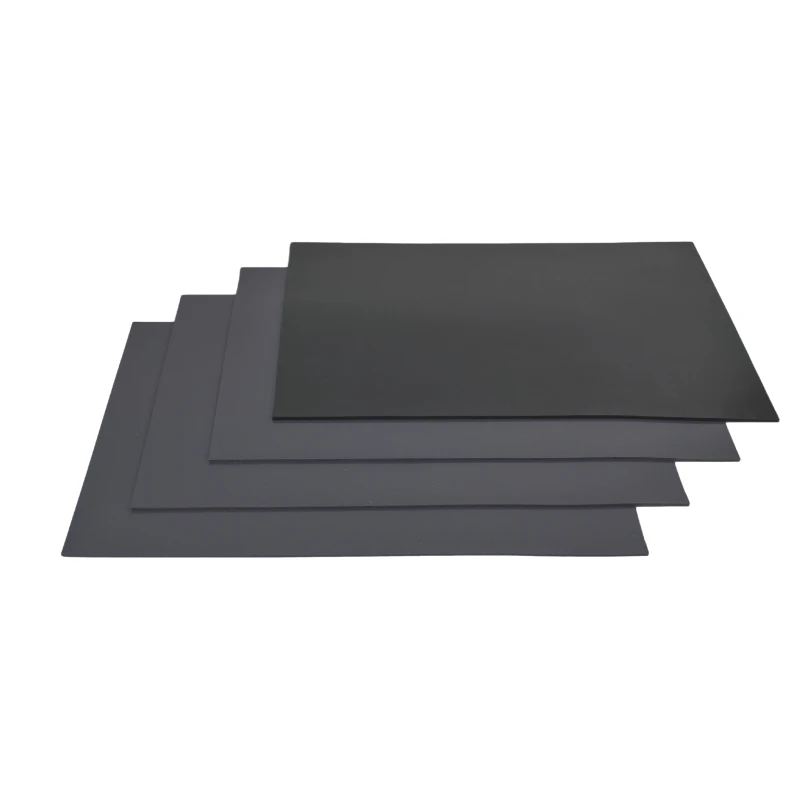

Thermal Conductivity Series

High-thermal-conductivity silicone compound

0.8-1.2 W/mK |

0.25℃·in²/W @50psi |

For EV cooling systems. UL94 V0 option

Wire & Cable Series

Platinum-cured silicone compounds for cable extrusion.

UL200℃ (aging test 210℃ 1440h) |

UL150℃ (aging test 158℃x1440) |

EV cable (180℃/200℃x3000)

Flame Retardant Series

Platinum-cured flame retardant silicone rubber

UL94 V0 (0.5mm/1.0mm/2.0mm) |

For connectors/cable jacketing |

Custom hardness 40-80 shore A

Industries We Serve

Discover how Mikon Technology’s advanced custom silicone rubber, silicone foam sheets, and high temperature silicone solutions drive innovation across diverse industries.

Electronics & Telecommunications

Automotive & Transportation

Industrial Equipment & Machinery

Consumer Products

LED Lighting & Displays

Defense & Aerospace

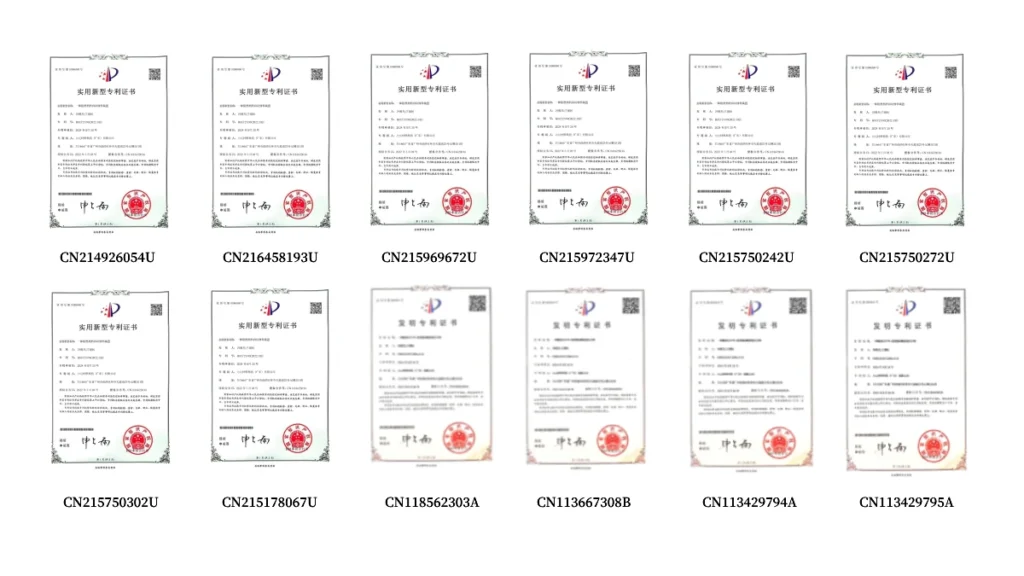

Certificates

IATF 16949:2016

ISO 9001:2015

12+ Patents

Your Silicone Questions, Answered

Yes, we offer comprehensive customization for custom silicone rubber. Hardness typically ranges from Shore A 10-80A. Colors can be matched to Pantone or samples. Performance aspects like flame retardants (UL94 V-0, HB), thermal conductivity, electrical conductivity, and anti-static properties can be tailored.

Our standard high temperature silicone can be used long-term from -60°C to 230°C. Some specialty grades can withstand transient temperatures up to 300°C or higher. Specific performance depends on the grade and application conditions.

For mass production, the MOQ is typically 300kg. For samples, MOQ is determined by development costs, process complexity, and your testing requirements, normally it’s 10kg/20kg/40kg. Please discuss details with our sales team.